Direct insertion of wiring provides safe, reliable termination of connections and is far quicker to use and less labour intensive, than screw-type connectors and stud-type connector blocks. It also provides the market’s most extensive range of jumpers and the fastest marking system, reducing marking time by 75 per cent.

Wago’s ATEX-approved Topjob S is suitable for connecting motors, diodes or LEDs in harsh environments from an offshore platform to hazardous atmospheres in the chemical industry.

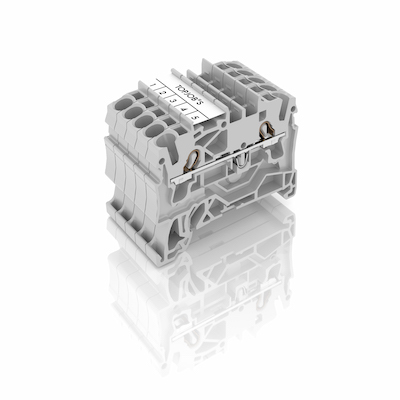

All conductor types from 0.14mm2 to 25mm2 including stripped, solid, stranded and fine-stranded with ferrules, can be pushed into the terminal block using Wago’s Push-in Cage Clamp technology, thereby eliminating the need to tighten screws. Proportional clamping means the spring adjusts automatically to the conductor size, so once the wire is pushed in, it is held securely and indefinitely. For connecting fine-stranded conductors an operating tool is inserted into the slot allowing for hands-free wiring. The tool also helps identify which clamping unit is open. To remove a conductor the tool is re-inserted into the slot.

The product family includes single, double, triple and quad deck terminal blocks as well as fuse, disconnect and diode terminals. The Topjob S rail mounted terminal blocks enable all of the above conductor types to connect one size greater than their rated cross section. This saves up to 25 per cent on wiring space and costs.

Topjob S can withstand shocks of up to 500G and vibrations of up to 20G, making it suitable even in harsh operating conditions such as underground, offshore, or in heavy industrial applications.

An extensive jumper range – step-down, adjacent, alternate, staggered, continuous and coloured – ensures all commoning tasks are covered. An adjacent jumper for the 2002 Series allows for continuous commoning, enabling an endless number of terminal blocks to be joined in a single jumper slot.

Topjob S rail-mounted terminal blocks are quickly and clearly labelled using continuous marking strips. Using free software, the strips can be printed with four lines of information with sufficient space to designate each module and its function. This ensures wiring accuracy and saves time and waste.