Mr Short, of Electroserve Installations in South Wales, knew that the electrical infrastructure in the factory’s location was unable to deliver more than 300Amps to the site which meant considering a new on-site sub-station at a cost of around £60,000. Until he did the calculations for a Marshall-Tufflex Power Factor Correction unit. The numbers showed that PFC could reduce the daily usage figure from 275Amps to 210Amps, giving an immediate 30% increase in site power capacity.

The PFC unit was specified together with a Marshall-Tufflex Voltis ECO 300Amp multi-tapping voltage optimisation system, which alone is estimated has saved the food producer around £7,500 per annum. Added to this is an annual saving of more than £1,800 because the company no longer pays reactive energy charges thanks to the PFC unit. The total investment in this energy management project was recouped in around nine months.

Installation of the PFC and Voltis ECO units was planned over two weekends with power outage required for just one Sunday when the factory was not operational, minimising disruption to production. Post installation the site’s Power Factor went from an unsatisfactory 0.71 to an impressive 0.99, with 1 (unity – the optimum level) displayed periodically. Importantly the PFC unit works intelligently to only correct the power supply when required, maximising savings.

Installation of the Power Factor Correction unit has delivered the extra power capacity required, eradicated reactive energy charges and ensured factory machinery and equipment, including large numbers of fridges and freezers, runs more efficiently and lasts longer. Power drops over long cable runs have also been improved. For Mr Short and the factory management it is a win-win situation, particularly since the manufacturer secured European grant aid to help fund the project.

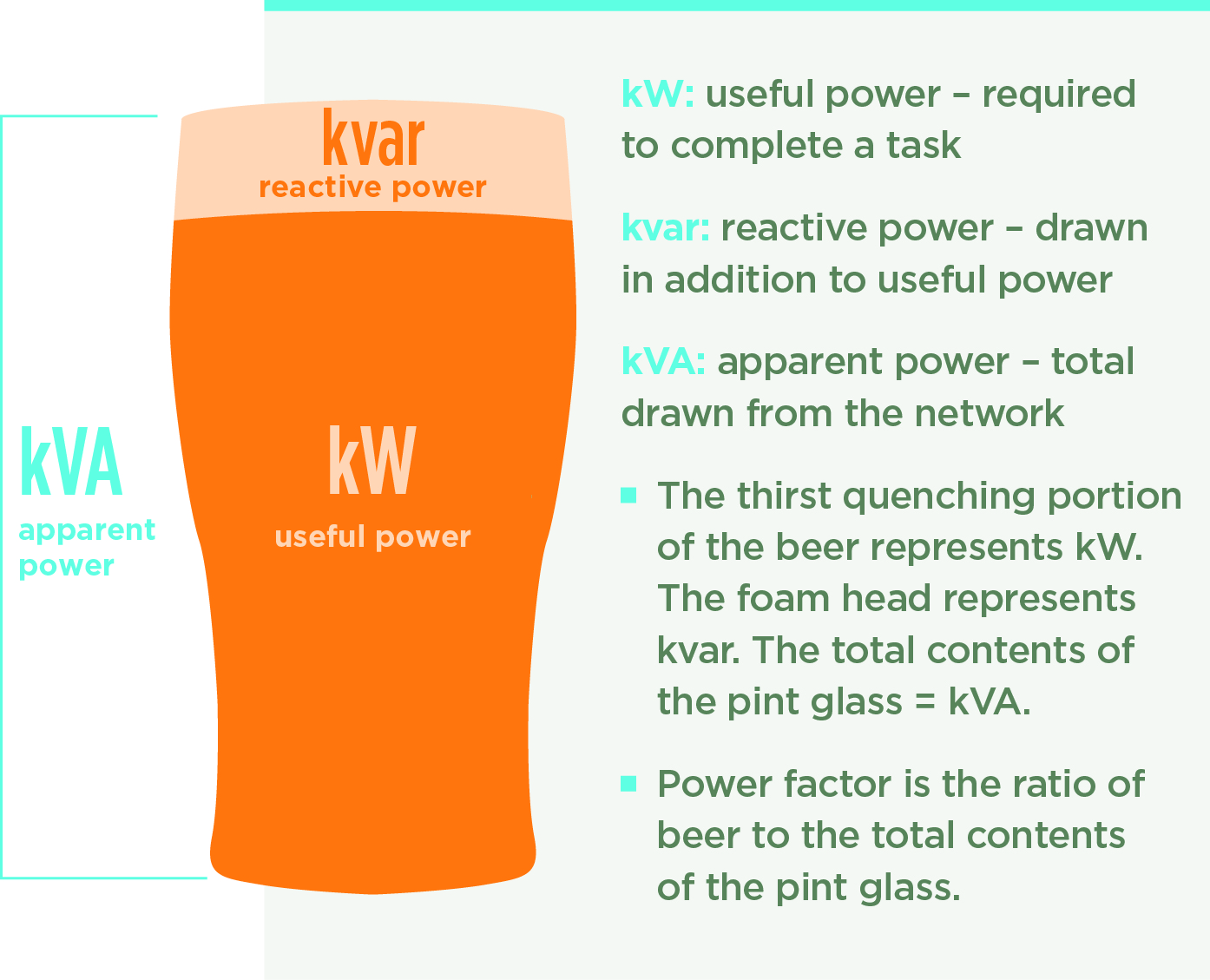

Power Factor Correction (PFC) is an established and proven energy saving technology used to improve the operating efficiency of electrical systems by reducing reactive power. Banks of capacitors neutralise the magnetising current, essentially balancing the inductive and capacitive elements. This reduces current drawn from the power distribution network and therefore also reduces bills and carbon emissions. For electrical contractors experienced in working with three-phase systems and currents of 300Amps or more Power Factor Correction units are straightforward to install.

Quicker installation, faster payback and greater in-use flexibility are offered by Marshall-Tufflex’s cost effective Voltis ECO range of 3-phase multi-tap voltage optimisation units, which appeal to users requiring an entry level ‘no-frills’ approach to voltage optimisation. The units are available direct from electrical wholesalers with three ‘tapping’ settings. Installers determine the ECO unit required (100A, 200A, 300A or 400A) and select the most appropriate tapping setting (which can be altered should mains voltage levels change significantly in the future). This multi-tap transformer approach drops the voltage by 11 per cent, nine per cent or six per cent, depending upon the level of incoming Mains (245Volts or above, 240Volts or 235Volts).